Use of Multi-Strand Stressing Jacks in Railway Projects

Railway projects are among the most complex infrastructure undertakings in the world. They require not just careful planning and execution but also highly specialized equipment to ensure durability and safety. Among these tools, multi-strand stressing jacks have earned a special place because of their ability to deliver high precision in large-scale railway works.

As railway networks expand with high-speed trains, freight corridors, and metro systems, the reliance on pre-stressed concrete railway girders and continuously welded rails has become stronger than ever. In such contexts, the multi-strand hydraulic jack for railway applications ensures that every girder, sleeper, and bridge deck can withstand the stresses of heavy trains and dynamic loads.

This article explores what multi-strand stressing jacks are, how they work, their role in railway projects, and why they are an irreplaceable part of modern heavy-duty railway construction tools.

What Are Multi-Strand Stressing Jacks?

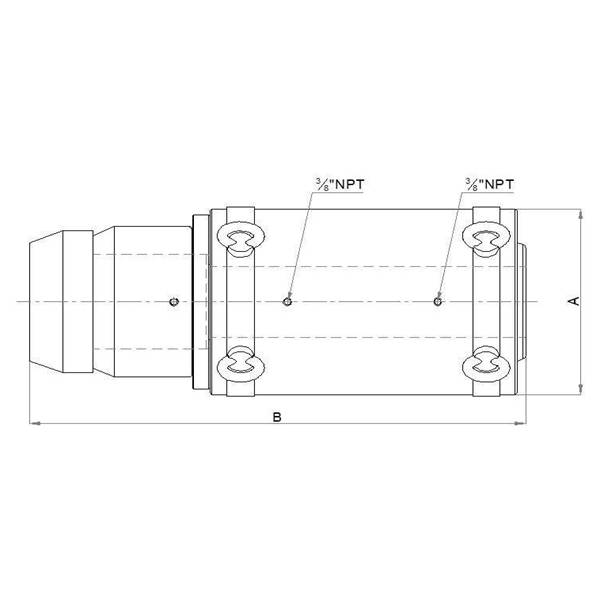

A multi-strand stressing jack is a type of hydraulic jack specifically designed to tension several strands of steel tendons at once. Instead of pulling one cable at a time, which is time-consuming and prone to uneven force distribution, these jacks can stress multiple strands simultaneously.

Key characteristics include:

- Capacity: Handles dozens of strands together, ideal for large-scale projects.

- Precision: Equal tension across all tendons ensures structural stability.

- Durability: Built with high-strength steel and advanced hydraulics for rugged conditions.

- Flexibility: Suitable for use in sleepers, girders, and welded rail projects.

By using these jacks, engineers achieve both efficiency and accuracy, reducing project delays while improving the quality of railway structures.

Importance of Stressing in Railway Projects

Railways rely heavily on pre-stressing and post-tensioning techniques for their core infrastructure. Without proper stressing, railway structures would not withstand the constant vibration, axle loads, and weather variations. Stressing jacks contribute in three critical ways:

1. Pre-Stressing Railway Sleepers

- Railway sleeper pre-stressing equipment is essential for ensuring sleepers are strong enough to resist repeated impacts.

- Multi-strand jacks apply uniform stress before concrete is cast, leading to crack-resistant and long-lasting sleepers.

2. Post-Tensioning Railway Girders and Bridges

- Post-tensioning jacks for railways are used after the concrete has hardened.

- This method allows engineers to construct long-span bridges capable of carrying heavy trains.

3. Continuously Welded Rail Stressing

- Modern rail networks avoid jointed tracks to reduce wear and tear.

- Continuously welded rail stressing involves stretching the rails with hydraulic jacks to manage thermal expansion and contraction.

Railway Bridge Construction Jacks

Railway bridges are among the most critical and expensive structures in any rail project. The safety of passengers and freight depends on their strength. Railway bridge construction jacks are indispensable because they:

- Pre-stress bridge girders to handle load-bearing efficiently.

- Strengthen deck slabs, which directly support rail tracks on bridges.

- Assist in repairs and retrofitting by reinforcing existing bridges with additional stress.

By using multi-strand stressing jacks, construction teams can work faster while ensuring that bridges last for decades without major repairs.

How Multi-Strand Hydraulic Jacks Work

Understanding how these jacks operate is key to appreciating their value in railway projects. The principle behind them lies in combining hydraulic power with precise anchoring systems. This ensures each strand carries an equal share of the load, eliminating weak points in the structure. Let’s break down how the process works in practice.

- Strand Setup: Multiple steel tendons are threaded through the jack’s anchoring system.

- Hydraulic Pressurization: A pump supplies pressure, pulling all strands at once.

- Anchoring: Once tension is achieved, wedges grip the strands firmly.

- Load Transfer: The jack releases pressure, transferring stress into the concrete element.

This method ensures every strand carries the same load, preventing weak points that might compromise railway safety.

Advantages of Multi-Strand Stressing Jacks in Railways

While the role of stressing in railways is clear, the choice of equipment makes all the difference. Multi-strand stressing jacks stand out not only for their capacity but also for the efficiency they bring to large-scale projects. Beyond speed, they ensure accuracy and safety that older methods often lack. Let’s look at the key advantages that make them the preferred choice for railway construction.

- Efficiency and Speed

- Stressing multiple tendons at the same time shortens project timelines.

- Stressing multiple tendons at the same time shortens project timelines.

- Uniform Stress Distribution

- Avoids imbalance and increases the durability of girders and sleepers.

- Avoids imbalance and increases the durability of girders and sleepers.

- High Accuracy

- Many modern systems feature digital monitoring for precise control.

- Many modern systems feature digital monitoring for precise control.

- Better Longevity of Structures

- Pre-stressed and post-tensioned components resist cracking and wear.

- Pre-stressed and post-tensioned components resist cracking and wear.

- Cost-Effectiveness

- Reduced maintenance costs over the lifecycle of railway assets.

- Reduced maintenance costs over the lifecycle of railway assets.

Applications Across Railway Infrastructure

Railway infrastructure relies on a wide range of components, each designed to handle extreme loads and constant wear. From sleepers to bridges, every structure must be reinforced with precision to ensure long-term safety. This is where multi-strand stressing jacks prove their versatility. Their applications span across nearly every stage of railway construction and maintenance, making them indispensable tools for modern rail projects.

1. Pre-Stressed Concrete Railway Sleepers

Sleepers are the backbone of any track system. Using railway sleeper pre-stressing equipment, multi-strand jacks ensure they can withstand heavy train operations and last much longer.

2. Railway Bridges

Bridges form crucial links in rail networks. With post-tensioning jacks for railways, engineers can design longer spans that need fewer supports, saving both material and cost.

3. Railway Girders

These massive beams support bridge decks. Stressing them using multi-strand jacks makes them capable of carrying both static and dynamic loads effectively.

4. Track Maintenance

Railway track maintenance equipment often includes stressing jacks to adjust, align, and maintain rails under continuous use.

5. Continuously Welded Rails

Hydraulic jacks ensure welded rails remain stable under temperature changes, preventing buckling and derailments.

Multi-Strand Stressing Jacks vs. Conventional Tools

In railway construction, tools are often judged by how much time they save and how reliably they perform. Traditional methods of stressing, using single-strand or mechanical systems, served their purpose for years, but they fall short in today’s large-scale, high-speed rail projects. Here’s how multi-strand stressing jacks compare:

| Feature | Multi-Strand Stressing Jacks | Conventional Tools |

| Speed | Stress dozens of strands at once, completing jobs faster. | One strand at a time, making projects longer. |

| Accuracy | Equipped with gauges and digital monitoring for precision. | Largely manual, dependent on operator skill. |

| Consistency | Equal load distribution across strands. | Uneven stress levels, risk of weak spots. |

| Efficiency | Lower manpower required, fewer delays. | Labor-intensive, slower project execution. |

| Durability of Output | Structures last longer with minimal maintenance. | Higher risk of cracks and structural fatigue. |

The difference isn’t just in the numbers, it’s in the peace of mind for engineers who know that their bridges, girders, and sleepers are stressed to perfection.

Safety Considerations in Railway Stressing

In railway construction, safety isn’t just a priority, it’s the foundation of every operation. Stressing, in particular, demands absolute precision, as even minor errors can compromise entire structures. This is where multi-strand hydraulic jacks bring a crucial layer of reliability. Their built-in features and design innovations directly enhance safety at every stage of the stressing process:

- Uniform Load Transfer: Prevents overstressing of individual tendons.

- Built-in Safety Valves: Avoids sudden release of hydraulic pressure.

- Locking Wedges: Secure tendons in place without slippage.

- Operator Control Systems: Modern jacks include digital sensors that track load in real time.

These safety features make them not just efficient, but also compliant with the strict safety standards expected in railway engineering.

Real-World Applications in Railway Projects

The true impact of multi-strand stressing jacks becomes clearer when looking at their use on the ground. From high-speed rail networks to metro systems and freight corridors, these tools prove their worth across diverse railway environments. They aren’t limited to just bridges or sleepers, they extend to track maintenance and welded rail systems too. Let’s explore some real-world scenarios where these jacks make a measurable difference.

1. High-Speed Rail Corridors

High-speed trains require track infrastructure that can withstand enormous dynamic forces. Multi-strand jacks ensure bridge girders and welded rails are stressed uniformly to handle vibrations and high axle loads.

2. Metro Rail Systems

In urban metro projects, railway sleeper pre-stressing equipment is widely used. Pre-stressed sleepers offer long service life despite frequent braking and acceleration of metro trains.

3. Freight Corridors

Dedicated freight corridors depend on heavy-duty structures. Railway bridge construction jacks help build girders capable of carrying higher tonnage trains safely.

4. Track Maintenance Programs

Multi-strand jacks are also part of railway track maintenance equipment. They’re used in adjusting and re-stressing welded rails during expansions or seasonal changes.

Future of Stressing Jacks in Railway Engineering

The next decade will bring transformative changes in how stressing jacks are used in railway projects. Some trends already emerging include:

- Digital Integration

- Smart jacks connected with IoT sensors to monitor stress in real-time.

- Data can be stored for future inspections and predictive maintenance.

- Smart jacks connected with IoT sensors to monitor stress in real-time.

- Automation & Robotics

- Automated stressing systems that reduce human involvement.

- Enhances safety and reduces chances of operator error.

- Automated stressing systems that reduce human involvement.

- Eco-Friendly Hydraulics

- Development of energy-efficient pumps with biodegradable oils.

- Reduces environmental footprint in construction projects.

- Development of energy-efficient pumps with biodegradable oils.

- Modular Systems

- Portable stressing jacks designed for quick setup in remote areas.

- Speeds up work in large-scale railway expansion projects.

- Portable stressing jacks designed for quick setup in remote areas.

These advancements will not only improve efficiency but also make railway infrastructure stronger and more sustainable.

Why Choose Bemco Jacks for Railway Projects?

With decades of expertise in hydraulic equipment, Bemco Jacks is a name trusted across industries. For railway projects, our multi-strand stressing jacks offer unmatched performance and reliability.

What Sets Us Apart?

- Engineering Excellence: Designed for heavy-duty use in bridges, girders, and tracks.

- Precision Built: Every jack is tested to ensure uniform load distribution.

- Durability: Made from high-strength materials, suitable for rugged railway sites.

- Versatility: From pre-stressing sleepers to post-tensioning bridge girders, our jacks meet diverse project needs.

- Service Support: Expert assistance to ensure smooth operation on-site.

When railway engineers choose Bemco Jacks, they choose peace of mind.

Conclusion

The future of railways depends on infrastructure that is stronger, safer, and built to last. Multi-strand stressing jacks in railway projects are at the heart of this progress, enabling efficient pre-stressing and post-tensioning across girders, bridges, sleepers, and continuously welded rails.

As India and the world expand their rail networks, whether high-speed passenger trains, freight corridors, or metro systems, the importance of precise, heavy-duty tools cannot be overstated. Multi-strand hydraulic jacks not only save time but also extend the life of critical railway assets.

For engineers, contractors, and infrastructure developers, choosing Bemco Jacks means investing in reliability, accuracy, and long-term value.

Enquire Now to learn how our multi-strand stressing solutions can power your next railway project.