Mono Strand Pulling Jacks

BEMCO JACKS offers high-performance Mono Strand Pulling Jacks, engineered for precision in post-tensioning and pre-stressing hydraulic jacks applications. Made from high-grade, hardened, and tempered alloy steel, these Strand Jacks are designed for durability and safety, featuring a pressure relief valve to prevent overpressurization during retraction. Tested to ASME standards and coated with corrosion-resistant hard chrome plating, they ensure long-lasting, reliable performance. The Mono Strand Jack is primarily used for single-hole tensioning but can also be applied for porous preloading, tensioning, troubleshooting, and handling high-strength steel wire bundles or steel strands of various sizes. Available for strands of 12.7, 15.2, and 15.7 sizes, these Pre Stressed Hydraulic Jacks are a perfect solution for your most demanding tensioning needs. For more details, connect with our experts on LinkedIn and explore the full potential of Bemco Jacks for your projects!

Features:

- Jacks are made of high grade, hardened & tempered alloy steel material.

- Safety pressure relief valve provided in return port, prevents overpressurization during retraction.

- Designed and tested as per ASME standards.

- All exposed surfaces are Hard chrome plated & blackodized for protection against corrosion.

- Master wedge can be provided on request.

Note:

- Higher capacity & customized solution request.

- Specifications are subjected to change due to continual improvement.

- Capacity & stroke specified are maximum safe limits. As safe practice, use at 80% of rating.

- Equipment to be operated by trained personnel.

- Do not change any factory settings.

- Do not dismantle the jack without consulting “Bemco Jacks”.

Application:

- Suitable for 12.7 / 15.2 /15.7 strands.

- Pulling slider & machined parts with HT strands.

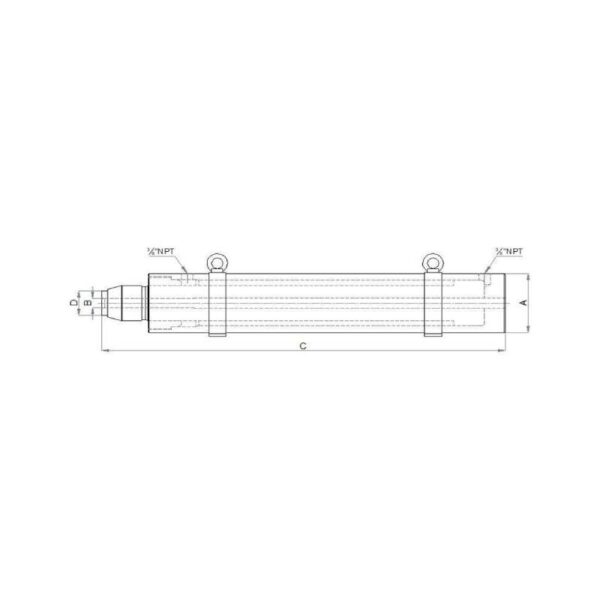

Mono Strand Pulling Jack – Rear Gripping

Capacity : 25 ton / Stroke : 750mm / Max.operating pressure : 700 kg/cm2

| Model | Capacity (Ton) |

Stroke (mm) |

Effective Area (sq.cm) |

Oil Reqd.(cc) | Max. Working Pressure (Kg/sq.c |

Approx Weight (Kg) |

A Outer Dia (mm) |

B Center Hole (mm) |

C Closed Height (mm) |

D Nose Dia (mm) |

| SSPJ 25/750 | 25 | 750 | 47.71 | 3726 | 525 | 72.7 | 120 | 20 | 1020 | 52 |